Which PFA Custom Teflon plastic injection mold consumables are required for quality control in the s

As the only material in the semiconductor manufacturing industry that can accommodate and transport high-purity chemicals used in the manufacturing process, fluoropolymers can achieve the extremely high stability and purity required for semiconductor manufacturing. In recent years, with the rapid expansion of the semiconductor industry, Custom teflon plastic injection mold The demand for products in the semiconductor industry is also showing a blowout mode.

Two specific types of fluoropolymers are commonly used: polytetrafluoroethylene (PTFE) and soluble polytetrafluoroethylene (PFA).

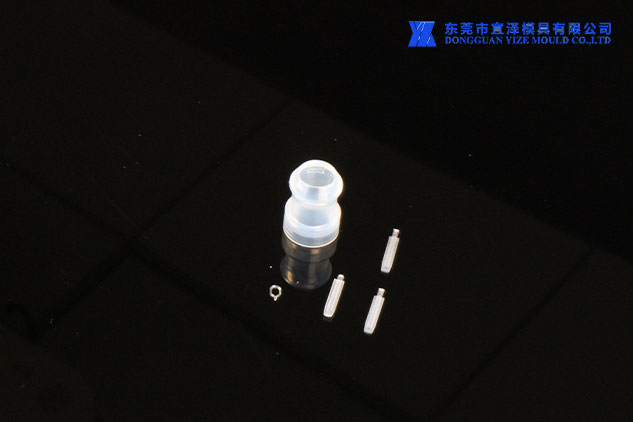

Since the molecular structure of PFA allows melt processing, it can be manufactured by traditional single-process processes such as injection molding, making the surface roughness of PFA products almost impossible to measure, and the finished product does not need any subsequent processing to prevent the introduction of pollution. Therefore, PFA can provide more safety protection for semiconductor process chemicals than PTFE, and is more suitable for the semiconductor industry.

1. Custom Teflon plastic injection mold Application - Preparation of high-purity strong acids (HF, HCL, HNO3)

Used for wet etching process and silicon wafer production process, high-purity chemicals in semiconductor manufacturing process, quality inspection of semi-finished products and finished products in each link

2. Custom Teflon plastic injection mold Application - VPD direct connection reagent bottle, long-term storage of various high-purity chemical reagents

3. Application - VPD-ICP-MS, ICP-QMS sample introduction, semiconductor manufacturing process various chemicals, semi-finished products (such as: trichlorosilane, phosphoric acid, high-purity silicon samples, hydrogen peroxide, nitric acid, hydrochloric acid, sulfuric acid, solar energy Grade silicon blocks, high silicon matrix samples, etc.) and silicon wafer impurity detection

4. Application - ultra-high purity gas liquefaction fluid transportation, corrosion-resistant pipeline integration

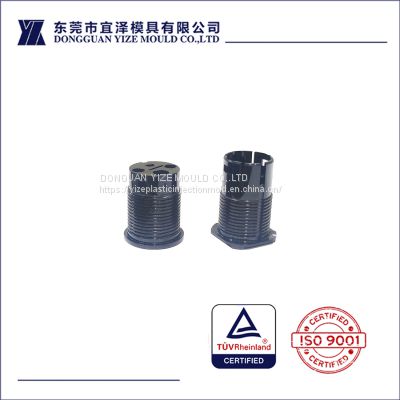

PFA Teflon plastic injection mold product: filter, tee, hose, etc.

Products——PFA valves, PFA fittings, PFA tees, PFA&FEP straight pipes & hoses, PFA scrubbers (impact filters), PFA filters, PTFE membranes, PFA nuts, and caps

Features - Corrosion resistance, suitable for various fluids, suitable for pipeline integration in various production processes of semiconductor production. The material is high-purity, with a wide range of categories, and the size specifications meet international standards, and the application range is wide. The PFA filter has a simple structure and is easy to operate. It is integrated in the delivery pipeline, which can further purify various highly corrosive gas-liquefied fluids, and the filter membrane can be replaced online, which greatly improves production efficiency.

5. Application - all processes in the pan-semiconductor manufacturing industry can be used

Products—Common tools for PFA in the laboratory: PFA washing bottle, PFA microcolumn/chromatographic column, PFA beaker, PFA clip, PFA dropping bottle, PFA large basin, PFA cleaning tank, PFA sealed tank, PFA syringe

This article is reproduced to https://www.yizemould.com/newsdetail-929.html

tyzieyize

Recently Posted

-

ABS 30% anti-static thermoplastics injection molding

May 4, 2023Case Study: Co-Molding 5 Products with One Set for ABS 30% anti-static thermoplastics injection moldingIntroduction:Our client required the production of five different ABS 30% anti-static thermoplastics injection molding, all to be co-molded using only one set of molds. The parts needed to meet specific surface quality requirements, with different areas designated as either A-Level or B-Level surfaces.A-Level Surface ReRead More -

Solenoid valve housings made of PBT 30% Engineering Plastics injection molding

May 4, 2023Case study of a problem that manufactures solenoid valve housings made of PBT 30% Engineering Plastics injection molding.The company found the following problems in the PBT 30% Engineering Plastics injection molding:1. The red circle has burrs, with a step difference of about 0.05;2. The appearance of the red circle is uneven and the knife lines are serious;3. The red circle has fiber marks and serious air trapping. ThisRead More -

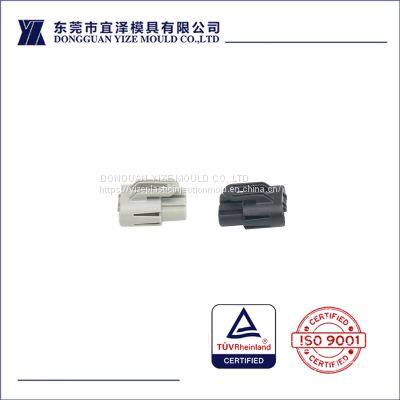

Case study Amphenol with LCP E130i Thermoplastics Precision Molded V-0 Material

May 4, 2023Introduction: Amphenol is a leading manufacturer of high-quality electronic connectors and interconnects systems. When Amphenol approached us to produce molded parts for their products using LCP E130i Thermoplastics Precision Molded V-0 material, we knew we had a challenging task ahead of us. This material is known for its high strength and excellent flame retardant properties, but it also has specific requirementsRead More -

About SMT high precision connector injection

February 6, 2023With the development of technology, many objects are now becoming lighter, smaller, and smarter, because they are easy to carry and easy to use, and the connector industry is no exception. Under the current trend of smaller and smaller connectors, it also poses a huge challenge to the material of the connector. Under this trend, high-temperature nylon and LCP emerged as the times require, and they shine in the field of SRead More