Radio-frequency high precision connector injection? Why Special engineering plastics?

For connectors, especially high-frequency and radio-frequency high precision connector injection, in addition to the excellent design and manufacturing process, another key factor that determines the quality of the product is the quality of its manufacturing materials. Special engineering plastics have the greatest use in connector applications. The advantage is insulation.

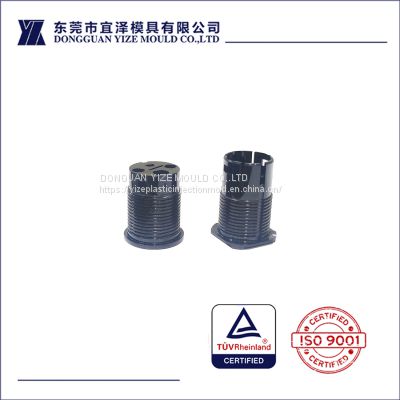

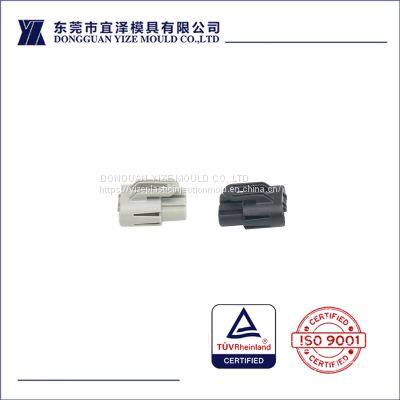

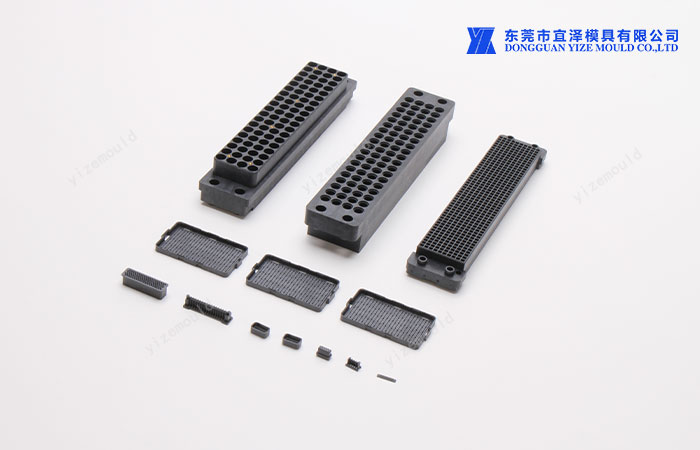

Usually the connectors are small, with a typical diameter between 3mm and 10mm. It requires excellent insulation properties and superb machinability, dimensional stability. At the same time, the smaller the dielectric loss, the better, so the dielectric constant of the plastic must be low. Taking all these factors into consideration, the most commonly used specialty plastic materials in connector applications are PEEK and PEI, which have the following advantages:

- Good electrification performance

PEEK and PEI have relatively low dielectric constants of 3.0 and 3.15 at 1kHz, respectively. The electrical properties radio-frequency high precision connector injection make the dielectric loss smaller.

- Good mechanical properties

The tensile strength, compressive strength and flexural strength of these two materials are all above 100Mpa. Moreover, the long-term working temperatures of PEEK and PEI are 260°C and 170°C, respectively. High thermal stability also enables the material to cope with working conditions of good quality.

In addition to the above two materials, other engineering plastics can also be used in the connector

PPS: polyphenylene sulfide

This kind of plastic has high service temperature, good mechanical strength and excellent insulation performance. But the dielectric constant is relatively higher than PEEK and PEI. So PPS is suitable for the housing of the、 radio-frequency high precision connector injection.

PTFE: polytetrafluoroethylene

This material exhibits a lower dielectric constant of 2.1 at 1kHz. But the mechanical properties are relatively low. PTFE is "softer" than other plastics when processed.

- Good insulation

Plastics only require good insulation for non-high frequency connectors. So literally any material that can meet the temperature and insulation needs is suitable, and in this high precision connector injection project these two leading plastics were used.

This article is reproduced to https://www.yizemould.com/newsdetail-934.html

tyzieyize

Recently Posted

-

ABS 30% anti-static thermoplastics injection molding

May 4, 2023Case Study: Co-Molding 5 Products with One Set for ABS 30% anti-static thermoplastics injection moldingIntroduction:Our client required the production of five different ABS 30% anti-static thermoplastics injection molding, all to be co-molded using only one set of molds. The parts needed to meet specific surface quality requirements, with different areas designated as either A-Level or B-Level surfaces.A-Level Surface ReRead More -

Solenoid valve housings made of PBT 30% Engineering Plastics injection molding

May 4, 2023Case study of a problem that manufactures solenoid valve housings made of PBT 30% Engineering Plastics injection molding.The company found the following problems in the PBT 30% Engineering Plastics injection molding:1. The red circle has burrs, with a step difference of about 0.05;2. The appearance of the red circle is uneven and the knife lines are serious;3. The red circle has fiber marks and serious air trapping. ThisRead More -

Case study Amphenol with LCP E130i Thermoplastics Precision Molded V-0 Material

May 4, 2023Introduction: Amphenol is a leading manufacturer of high-quality electronic connectors and interconnects systems. When Amphenol approached us to produce molded parts for their products using LCP E130i Thermoplastics Precision Molded V-0 material, we knew we had a challenging task ahead of us. This material is known for its high strength and excellent flame retardant properties, but it also has specific requirementsRead More -

About SMT high precision connector injection

February 6, 2023With the development of technology, many objects are now becoming lighter, smaller, and smarter, because they are easy to carry and easy to use, and the connector industry is no exception. Under the current trend of smaller and smaller connectors, it also poses a huge challenge to the material of the connector. Under this trend, high-temperature nylon and LCP emerged as the times require, and they shine in the field of SRead More