Home > Company News > OEM high precision plastic injection mold what demand for a mold core?

Company News

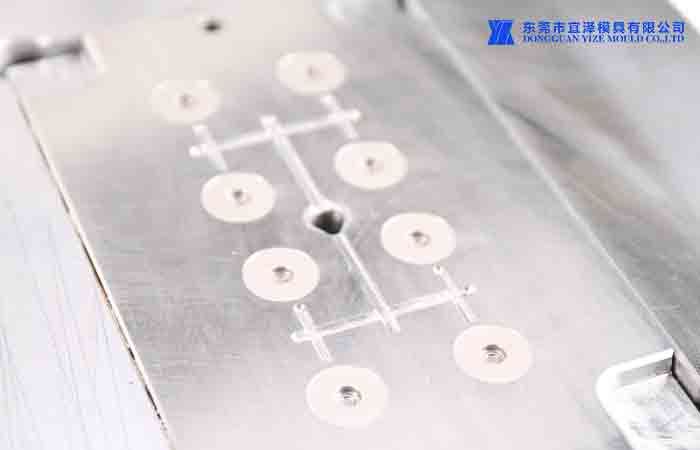

We all know that OEM high precision plastic injection mold can only be transferred to mass production after being verified as ok, so what are the requirements for mold core runners during mold acceptance?

Here are my four small points about the OEM high precision plastic injection mold:

1. It is necessary to check whether the runner has been polished

2. Whether the mold core glue mouth workpieces such as the submersible glue mouth/dispensing mouth are polished

3. Avoid chipping on the surface of the mold core

What is OEM high precision plastic injection mold in a swarf?

The nozzle needs to be polished. Generally, the submersible rubber nozzle is processed by EDM discharge or directly with a drill nozzle. The surface is relatively rough. When the plastic material flows through, it will remain on the mold core or on the nozzle. When it comes out, there will be a phenomenon of strong stripping, resulting in a swarf.

The swarf is caused by the unclean plastic opening during the molding and feeding process, resulting in dandruff-like powder objects that are punched into the surface of the mold cavity by high pressure during the secondary injection molding, resulting in surface defects of the product. The reason is still caused by the cross-sectional shape of the rubber mouth.

Suggested improvement plan for high precision plastic injection mold equipment:

1). The rubber feeding thimble should be pushed out in a delayed manner.

2). Change the shape of the head of the rubber mouth so that it has enough strength not to be torn at the moment of breaking. The blade must be sharp and be made into a replaceable insert piece (SKD61 HRC52)!

4. Whether there is exhaust at the end of the main channel, and the poor exhaust of the injection mold will bring a series of harm to the quality of plastic parts and many other aspects....

eriomoldwfuiq

https://www.yizemould.com/newsdetail-886.html

-

China Manufacturer Custom Metal Pm Powder Metallurgy Parts internal gear external spur gear internal spur gear cylindrical gear sprial bevel gear straight bevel

-

ERSA wave soldering accessories high imitation selective wave soldering nozzle, standard size are in stock

-

Customized hot staming metal component mould

-

Customized cheap Chinese stamping die mould for Auto parts

-

OEM Customized Stamping Parts Metal Stamping die progressive die

-

18 years Stamping mold factory progressive die Stamping Die Tooling for auto parts

-

Vehicle model car mold metal stamping tools progressive die Stamping Die Tooling for auto parts

-

High quality Customized hot stamping vehicle metal parts mould

-

Customized Cheap Product Sheet Metal Stamping Punch Mould Tooling

-

ISO9001 factory Free 3D design custom precision metal press tool from Sobede

-

Customized stamping molds for automotive components

-

Metal Bending Stamping Metal Part OEM vehicles car automotive parts accessories metal sintered stainless steel powder metallurgy technique company manufacture

-

Plastic PP Membrane Hot Chamber vertical Frame membrane filter press plate mold

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15 stainless picture frame OEM Machine Mechanical stainless steel fabrication For Furniture Parts

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15stainless picture frame OEM Machine Mechanical stainless steel fabrication For Furniture Parts

-

Hexagonal Tube & Pentagonal shape Tube Machinery

-

Steel Triangle Tube Roll Forming Machine Manufacturer

-

Welding Hardware Sheet Metal Blanks Stamping Parts with OEM vehicle parts car automotive accessories metal sintered stainless steel in technique company manufacture

-

High Precision Sintered Pm Powder Metal Components speed reducer gear positive speed gearbox front terminal end gear double gear herring bone gear angle grinder

-

OEM Powder Metallurgy Mold Parts Suppliers Driven External Spur Enicycloid Bevel Gear sun gear for industry

-

Thick Flat Oval Tube Roll Forming Machine

-

Multiple Steel Tube 8 Types Square Tube Roll Forming Machine 8 in 1

-

Thick Oil Tube Roll Forming Machine Rectangular Pipe 6mm

-

Auto half shaft upsetting processing,camshaft,sucker rod,valve stem and other unregular forgings processing