Home > Company News > Improve the connector mould process: a case study

Company News

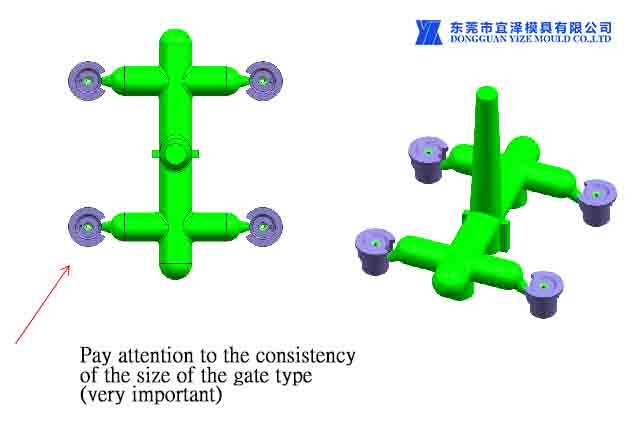

Connector Mould process Requirements are as follows:

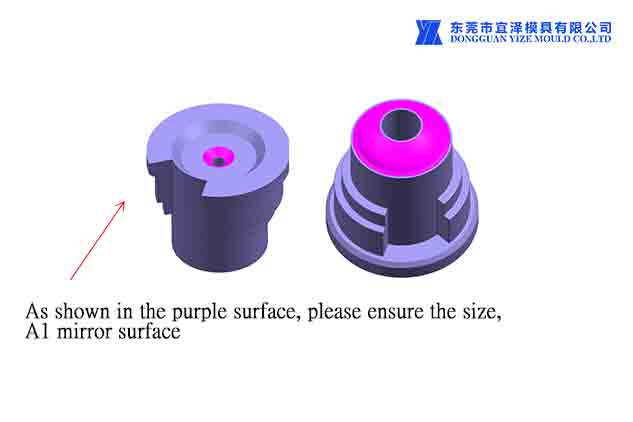

1. Pursue the mirror discharge matte effect while maintaining the size

2. Customizable lettering

3. No burrs, lack of material, shrinkage, cracks, scorch, strain, chromatic aberration, and other defects for Connector Moulding

4. Pay attention that this material is easy to cloak, pay attention to the roughness of the parting surface (fine grinding)

5. The product cavity accuracy is controlled within ±0.005

How to solve problems

1. Unsaturated mold, with burrs;

2. Serious deformation / inconsistent size of hole cloak;

3. Dip the front mold;

4. The appearance is inconsistent;

Reason

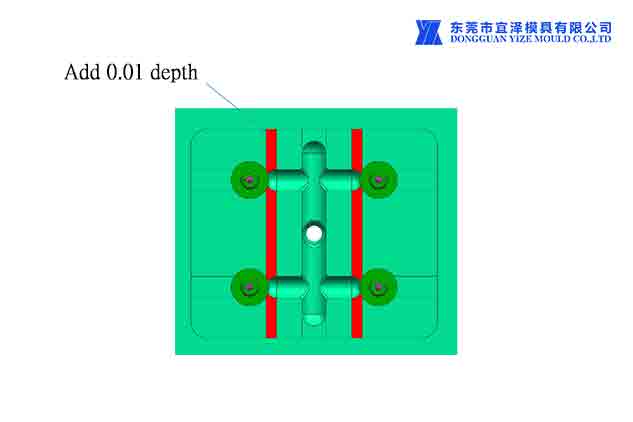

1. Connector Mould process Poor exhaust;

How to do?

â‘ Increase exhaust gas;

②After the assembly of all sizes is OK, make the pattern uniformly; similar products need to improve the position of the glue feeding method

2. The glue feeding method is unreasonable, and there are certain reasons for the material and machine adjustment;

How to do?

â‘ Improve the glue position, feed glue at two wall thickness positions, increase the thimble,

② Bottom hole inserts increase the draft angle

③Increase the mold temperature

â‘ŁRe-select materials

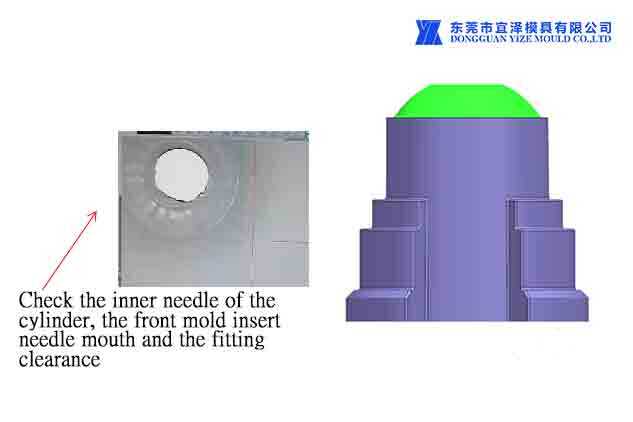

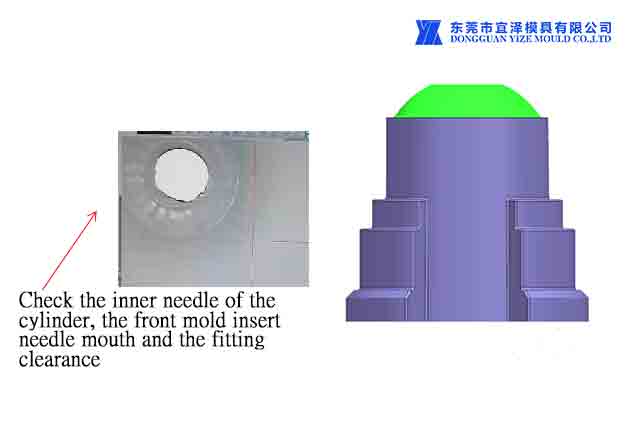

3. The glue position of the needle is long, and there is no draft angle;

How to do?

â‘ Connector Mould process the back of the ejector pad is 0.13mm

②The inner needle and the back needle of the cylinder are adjusted and replaced at the same time

③Precise positioning Front and rear die exchange and installation

Connector Mould manufacturers to have to complete sometimes has to work in parallel with the customer, and must review with the customer within the mold maker.

Improvements, modifications and selections made at the beginning of the project will most likely affect the end result, including part cost.

https://www.yizemould.com/newsdetail-888.html

eriomoldwfuiq

-

China Manufacturer Custom Metal Pm Powder Metallurgy Parts internal gear external spur gear internal spur gear cylindrical gear sprial bevel gear straight bevel

-

ERSA wave soldering accessories high imitation selective wave soldering nozzle, standard size are in stock

-

Customized hot staming metal component mould

-

Customized cheap Chinese stamping die mould for Auto parts

-

OEM Customized Stamping Parts Metal Stamping die progressive die

-

18 years Stamping mold factory progressive die Stamping Die Tooling for auto parts

-

Vehicle model car mold metal stamping tools progressive die Stamping Die Tooling for auto parts

-

High quality Customized hot stamping vehicle metal parts mould

-

Customized Cheap Product Sheet Metal Stamping Punch Mould Tooling

-

ISO9001 factory Free 3D design custom precision metal press tool from Sobede

-

Customized stamping molds for automotive components

-

Metal Bending Stamping Metal Part OEM vehicles car automotive parts accessories metal sintered stainless steel powder metallurgy technique company manufacture

-

Plastic PP Membrane Hot Chamber vertical Frame membrane filter press plate mold

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15 stainless picture frame OEM Machine Mechanical stainless steel fabrication For Furniture Parts

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15stainless picture frame OEM Machine Mechanical stainless steel fabrication For Furniture Parts

-

Hexagonal Tube & Pentagonal shape Tube Machinery

-

Steel Triangle Tube Roll Forming Machine Manufacturer

-

Welding Hardware Sheet Metal Blanks Stamping Parts with OEM vehicle parts car automotive accessories metal sintered stainless steel in technique company manufacture

-

High Precision Sintered Pm Powder Metal Components speed reducer gear positive speed gearbox front terminal end gear double gear herring bone gear angle grinder

-

OEM Powder Metallurgy Mold Parts Suppliers Driven External Spur Enicycloid Bevel Gear sun gear for industry

-

Thick Flat Oval Tube Roll Forming Machine

-

Multiple Steel Tube 8 Types Square Tube Roll Forming Machine 8 in 1

-

Thick Oil Tube Roll Forming Machine Rectangular Pipe 6mm

-

Auto half shaft upsetting processing,camshaft,sucker rod,valve stem and other unregular forgings processing