Home > Company News > Notes for PEI injection molding

Company News

PEI (polyether) has strong high temperature stability, toughness and strength, and is often used to make high temperature and heat resistant devices. At the same time PEI precision injection molding will have high injection temperature, injection molding process is complex, product performance is not stable and other difficulties. High requirements for equipment, process control and operators. So today, the appropriate mold to explain the attention of PEI injection molding processing.

1. Material drying: the drying equipment must be able to reach the temperature of at least 120ā and. The drying system shall BE ABLE TO MAINTAIN THE RECOMMENDED DRYING TIME in a continuous operation, USUALLY 6 hours under the conditions described above.

2. Process control and monitoring: the precision injection molding process should be controlled by screw speed and position, not by pressure and time control. This ensures that injection rate and filling time are controlled.

3. Shutdown and cleaning: after the completion of precision injection molding operation, the use of thermal performance of more than 370ā suitable cleaning material, no plastic left in the molding machine cylinder.

4. Injection speed: increase the injection speed as much as possible without causing embrittlement.

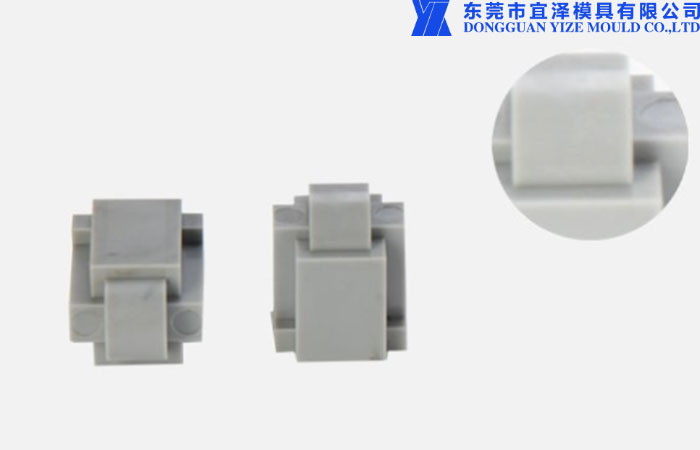

plastic injection molding parts-- PEI

Yize mold is located in the "Chinese mold town" known as Dongguan Chang 'an Town, China, fifteen years, Yize mold focus on "mold design and manufacturing, precision plastic mold manufacturing,high precision plastic injection"

https://www.yizemould.com/newsdetail-899.html

saefeyiz

-

China Manufacturer Custom Metal Pm Powder Metallurgy Parts internal gear external spur gear internal spur gear cylindrical gear sprial bevel gear straight bevel

-

ERSA wave soldering accessories high imitation selective wave soldering nozzle, standard size are in stock

-

Customized hot staming metal component mould

-

Customized cheap Chinese stamping die mould for Auto parts

-

OEM Customized Stamping Parts Metal Stamping die progressive die

-

18 years Stamping mold factory progressive die Stamping Die Tooling for auto parts

-

Vehicle model car mold metal stamping tools progressive die Stamping Die Tooling for auto parts

-

High quality Customized hot stamping vehicle metal parts mould

-

Customized Cheap Product Sheet Metal Stamping Punch Mould Tooling

-

ISO9001 factory Free 3D design custom precision metal press tool from Sobede

-

Customized stamping molds for automotive components

-

Metal Bending Stamping Metal Part OEM vehicles car automotive parts accessories metal sintered stainless steel powder metallurgy technique company manufacture

-

Plastic PP Membrane Hot Chamber vertical Frame membrane filter press plate mold

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15 stainless picture frame OEM Machine Mechanical stainless steel fabricationāFor Furniture Parts

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15stainless picture frame OEM Machine Mechanical stainless steel fabricationāFor Furniture Parts

-

Hexagonal Tube & Pentagonal shape Tube Machinery

-

Steel Triangle Tube Roll Forming Machine Manufacturer

-

Welding Hardware Sheet Metal Blanks Stamping Parts with OEM vehicle parts car automotive accessories metal sintered stainless steel in technique company manufacture

-

High Precision Sintered Pm Powder Metal Components speed reducer gear positive speed gearbox front terminal end gear double gear herring bone gear angle grinder

-

OEM Powder Metallurgy Mold Parts Suppliers Driven External Spur Enicycloid Bevel Gear sun gear for industry

-

Thick Flat Oval Tube Roll Forming Machine

-

Multiple Steel Tube 8 Types Square Tube Roll Forming Machine 8 in 1

-

Thick Oil Tube Roll Forming Machine Rectangular Pipe 6mm

-

Auto half shaft upsetting processing,camshaft,sucker rod,valve stem and other unregular forgings processing