Home > Company News > Show some defects of plastic injection molding parts

Company News

Due to the complex processing technology, there will be various situations in precision injection molding parts. Today, I will take you to understand the causes and solutions of defects of plastic injection molding parts

The level difference refers to the deviation of the matching between the two mold inserts or the parting surfaces of the front and rear molds due to the deviation of the machining accuracy.

Solution

1. The mold gap is too small. It is generally recommended that the overall mold gap is not well aligned, including the mold base and mold guide components.

The reasons such as insufficient precision of the turret sleeve are too high, mainly due to the overheating of the punch caused by the continuous long-term stamping of the same mold.

2. It should be checked whether the gap of the mold is reasonable. If the gap of the mold is not suitable, it is easy to cause oil with a lot of waste.

3. The positioning of the mold base frame is not standardized, the assembly of the shovel is not in place, the inserts are not connected smoothly, and the imitation operation is not standardized.

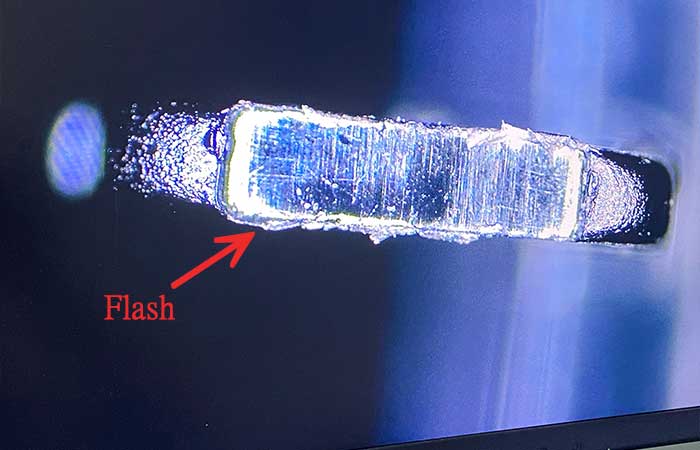

Flash, also known as overflow, burr, burr, etc., mostly occurs at the opening and closing positions of the mold, such as the parting surface of the moving mold and the static mold, the sliding part of the slider, the absolute gap of the insert, and the hole of the ejector. etc., flash is largely due to the failure of the clamping force of the mold or machine.

Causes and Solutions

1. Unbalanced distribution of mold cavity or insufficient parallelism cause unbalanced force and cause local flash and local dissatisfaction. The runner should be placed in the center of mass symmetry as much as possible without affecting the integrity of the part.

2. When the movable components and sliding cores in the mold are unbalanced, the flash will be caused.

3. When the mold is poorly vented, the pressurized air will cause the parting surface of the mold to expand and flash. A good exhaust system should be set up, or an exhaust ditch should be dug on the parting surface.

Causes and Solutions

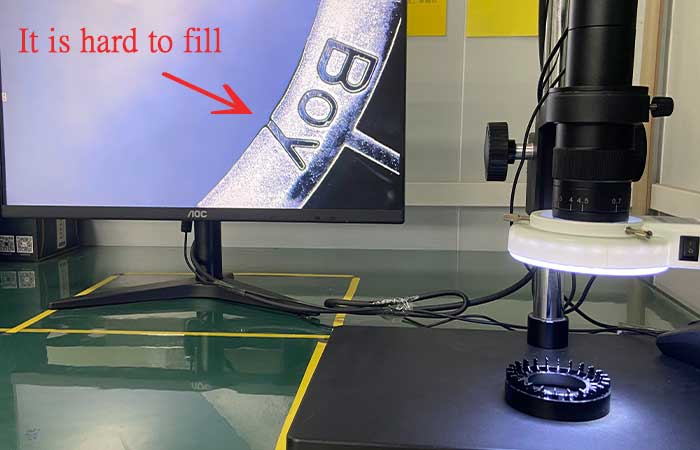

1. The structural design of the plastic parts is unreasonable. When the thickness of the plastic part is not proportional to the length, the shape is very complex and the molding area is large, the melt flow is easily blocked at the entrance of the thin-walled part of the plastic part, making it difficult to fill the cavity. Therefore, when designing the shape and structure of the plastic part, it should be noted that the thickness of the plastic part is related to the limit flow length when the melt is filled. ;

2. The material has poor fluidity. When the fluidity of the raw material is poor, the structural parameters of the mold are the main reasons for the undershot. Therefore, the stagnation defect of the mold gating system should be improved, such as reasonable setting of the sprue position, enlargement of the gate, runner and sprue size, and the use of larger nozzles. At the same time, an appropriate amount of additives can be added to the raw material formula to improve the flow properties of the resin. In addition, it is also necessary to check whether the amount of recycled materials in the raw materials is excessive, and appropriately reduce the amount thereof.

3. The mold temperature is too low. After the melt enters the low temperature mold cavity, it will cool too fast to fill all corners of the cavity.

The rapid development of the manufacturing industry has put forward higher requirements for professional plastic injection molding parts testing tasks. Traditional manual methods have been unable to meet the high-precision, rapid and even real-time dynamic testing requirements of large-scale products. Machine vision technology uses digital images as a means of obtaining information, and is closely integrated with computer graphics, automation technology and other related fields, and is very suitable for the detection of vulnerable items with high precision requirements.

saefeyiz

https://www.yizemould.com/newsdetail-897.html

-

China Manufacturer Custom Metal Pm Powder Metallurgy Parts internal gear external spur gear internal spur gear cylindrical gear sprial bevel gear straight bevel

-

ERSA wave soldering accessories high imitation selective wave soldering nozzle, standard size are in stock

-

Customized hot staming metal component mould

-

Customized cheap Chinese stamping die mould for Auto parts

-

OEM Customized Stamping Parts Metal Stamping die progressive die

-

18 years Stamping mold factory progressive die Stamping Die Tooling for auto parts

-

Vehicle model car mold metal stamping tools progressive die Stamping Die Tooling for auto parts

-

High quality Customized hot stamping vehicle metal parts mould

-

Customized Cheap Product Sheet Metal Stamping Punch Mould Tooling

-

ISO9001 factory Free 3D design custom precision metal press tool from Sobede

-

Customized stamping molds for automotive components

-

Metal Bending Stamping Metal Part OEM vehicles car automotive parts accessories metal sintered stainless steel powder metallurgy technique company manufacture

-

Plastic PP Membrane Hot Chamber vertical Frame membrane filter press plate mold

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15 stainless picture frame OEM Machine Mechanical stainless steel fabrication For Furniture Parts

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15stainless picture frame OEM Machine Mechanical stainless steel fabrication For Furniture Parts

-

Hexagonal Tube & Pentagonal shape Tube Machinery

-

Steel Triangle Tube Roll Forming Machine Manufacturer

-

Welding Hardware Sheet Metal Blanks Stamping Parts with OEM vehicle parts car automotive accessories metal sintered stainless steel in technique company manufacture

-

High Precision Sintered Pm Powder Metal Components speed reducer gear positive speed gearbox front terminal end gear double gear herring bone gear angle grinder

-

OEM Powder Metallurgy Mold Parts Suppliers Driven External Spur Enicycloid Bevel Gear sun gear for industry

-

Thick Flat Oval Tube Roll Forming Machine

-

Multiple Steel Tube 8 Types Square Tube Roll Forming Machine 8 in 1

-

Thick Oil Tube Roll Forming Machine Rectangular Pipe 6mm

-

Auto half shaft upsetting processing,camshaft,sucker rod,valve stem and other unregular forgings processing