Home > Company News > Raw material for plastic injection molding parts has molding flash

Company News

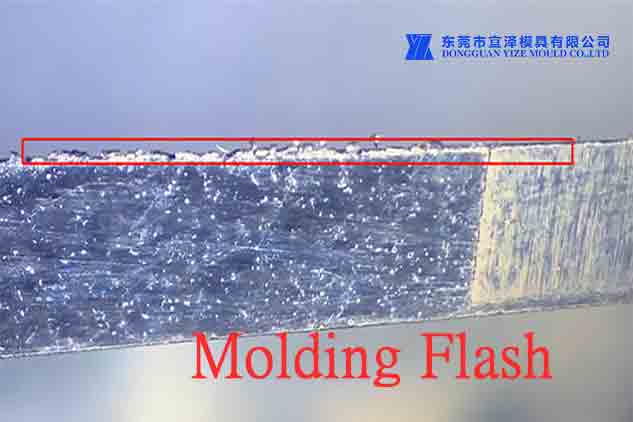

Molding Flash also known as flashing, overflowing, flashing, etc., mostly occurs at the point and place of the mold.

Different Raw material for plastic injection molding parts have different physical properties, and the overflow value is also different.

(1) If the viscosity of the plastic is too high or too low, flash may appear

Plastics with low viscosity, such as nylon, polyethylene, polypropylene, etc., should increase the clamping force; plastics with strong water absorption or water-sensitive plastics will greatly reduce the flow viscosity at high temperatures and increase the possibility of flashing. These plastics must be thoroughly dried; plastics with too much recycled content will also decrease in viscosity, and if necessary, the retained components should be replenished. If the viscosity of the plastic is too high, the flow resistance will increase, and a large back pressure will increase the cavity pressure, resulting in insufficient clamping force and flashing.

(2) When the particle size of raw material for plastic injection molding parts is not uniform, the feeding amount will vary, and the parts will be dissatisfied or flashed.

The following are the overrun values of our commonly used connector materials:

LCP material is 0.0015mm

PA66 material is 0.006-0.008mm

PEEK material is 0.008mm

PPSU material is 0.0005mm

PBT material is 0.008mm

Generally, plastic injection molding parts defects the locations where flash is likely to occur are:

The parting surface of the mold, the sliding part of the slider, the gap of the insert, the hole of the ejector, etc.

If the overflow is not solved in time, Raw material for plastic injection molding parts will further expand, so that the imprinting mold will form a partial collapse, causing permanent damage. The overflow of the gap of the insert and the hole of the ejector pin will also cause the product to be stuck on the mold and affect the demoulding.

https://www.yizemould.com/newsdetail-895.html

saefeyiz

-

China Manufacturer Custom Metal Pm Powder Metallurgy Parts internal gear external spur gear internal spur gear cylindrical gear sprial bevel gear straight bevel

-

ERSA wave soldering accessories high imitation selective wave soldering nozzle, standard size are in stock

-

Customized hot staming metal component mould

-

Customized cheap Chinese stamping die mould for Auto parts

-

OEM Customized Stamping Parts Metal Stamping die progressive die

-

18 years Stamping mold factory progressive die Stamping Die Tooling for auto parts

-

Vehicle model car mold metal stamping tools progressive die Stamping Die Tooling for auto parts

-

High quality Customized hot stamping vehicle metal parts mould

-

Customized Cheap Product Sheet Metal Stamping Punch Mould Tooling

-

ISO9001 factory Free 3D design custom precision metal press tool from Sobede

-

Customized stamping molds for automotive components

-

Metal Bending Stamping Metal Part OEM vehicles car automotive parts accessories metal sintered stainless steel powder metallurgy technique company manufacture

-

Plastic PP Membrane Hot Chamber vertical Frame membrane filter press plate mold

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15 stainless picture frame OEM Machine Mechanical stainless steel fabrication For Furniture Parts

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15stainless picture frame OEM Machine Mechanical stainless steel fabrication For Furniture Parts

-

Hexagonal Tube & Pentagonal shape Tube Machinery

-

Steel Triangle Tube Roll Forming Machine Manufacturer

-

Welding Hardware Sheet Metal Blanks Stamping Parts with OEM vehicle parts car automotive accessories metal sintered stainless steel in technique company manufacture

-

High Precision Sintered Pm Powder Metal Components speed reducer gear positive speed gearbox front terminal end gear double gear herring bone gear angle grinder

-

OEM Powder Metallurgy Mold Parts Suppliers Driven External Spur Enicycloid Bevel Gear sun gear for industry

-

Thick Flat Oval Tube Roll Forming Machine

-

Multiple Steel Tube 8 Types Square Tube Roll Forming Machine 8 in 1

-

Thick Oil Tube Roll Forming Machine Rectangular Pipe 6mm

-

Auto half shaft upsetting processing,camshaft,sucker rod,valve stem and other unregular forgings processing