Home > Company News > Show the tungsten carbide Cold Forming die manufacturers tips

Company News

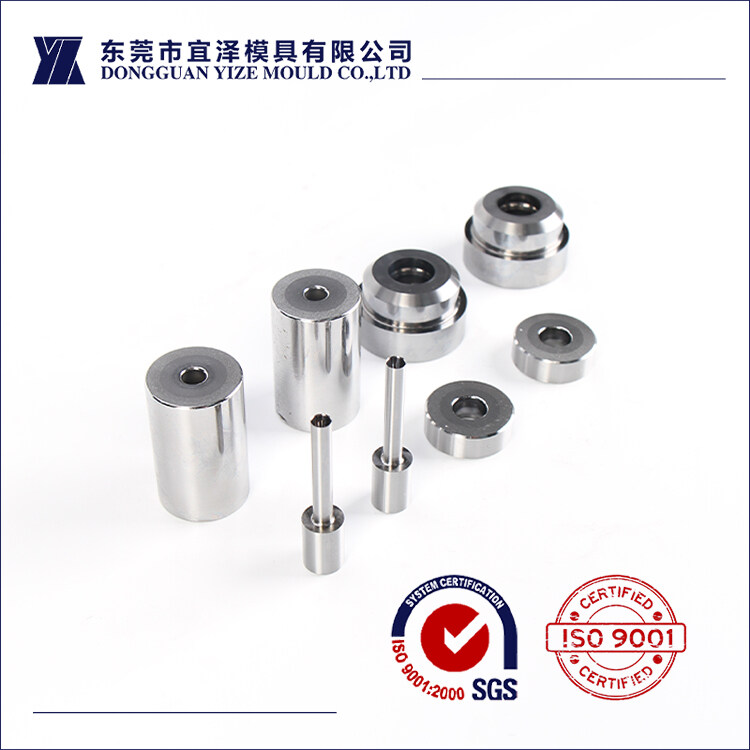

Features of tungsten carbide Cold Forming die process:

1. Cold heading is carried out at room temperature. Cold heading can improve the mechanical properties of metal parts.

2. The cold heading forging process can increase the material rate. It is a pressure processing method based on plastic deformation, which can achieve less or no cutting. Generally, the utilization rate of materials is above 85%, and the highest can reach more than 99%.

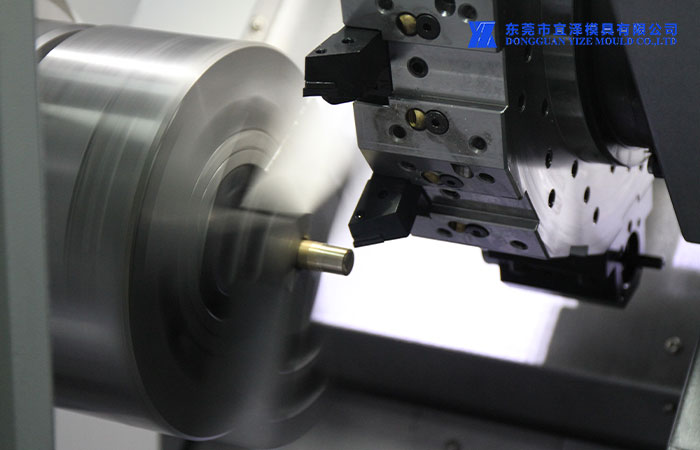

3.The tungsten carbide Cold Forming die manufacturers want to improve production efficiency. The time and process of deformation of metal products are relatively short, especially processing parts on multi-station forming machines, which can greatly improve productivity.

4. The cold heading forging process can improve the surface roughness of the product and ensure the precision of the product.

What should tungsten carbide Cold Forming die manufacturers do if I encounter mold cracking?

More and more people choose 8566 mold steel to solve the problem of mold cracking for screw cold emblem molds. DC53, LD, and cemented carbide are used for screw cold emblem molds. Many times, cracking problems cannot be solved, which is caused by the poor toughness of DC53, LD, and cemented carbide. For screw cold emblem molds, 8566 mold steel toughness can be used, which is 4 times that of high-speed steel SKH-9 and twice that of D2; it can solve problems that cannot be solved by high-hardness mold steels such as D2.DC53, LD, and SKH-9. Cracking problem; the hardness of 8566 is HRC58-60, which is used for cold emblem molds without cracking or collapsing, and the mold life is long.

https://www.yizemould.com/newsdetail-919.html

saefeyiz

-

China Manufacturer Custom Metal Pm Powder Metallurgy Parts internal gear external spur gear internal spur gear cylindrical gear sprial bevel gear straight bevel

-

ERSA wave soldering accessories high imitation selective wave soldering nozzle, standard size are in stock

-

Customized hot staming metal component mould

-

Customized cheap Chinese stamping die mould for Auto parts

-

OEM Customized Stamping Parts Metal Stamping die progressive die

-

18 years Stamping mold factory progressive die Stamping Die Tooling for auto parts

-

Vehicle model car mold metal stamping tools progressive die Stamping Die Tooling for auto parts

-

High quality Customized hot stamping vehicle metal parts mould

-

Customized Cheap Product Sheet Metal Stamping Punch Mould Tooling

-

ISO9001 factory Free 3D design custom precision metal press tool from Sobede

-

Customized stamping molds for automotive components

-

Metal Bending Stamping Metal Part OEM vehicles car automotive parts accessories metal sintered stainless steel powder metallurgy technique company manufacture

-

Plastic PP Membrane Hot Chamber vertical Frame membrane filter press plate mold

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15 stainless picture frame OEM Machine Mechanical stainless steel fabrication For Furniture Parts

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15stainless picture frame OEM Machine Mechanical stainless steel fabrication For Furniture Parts

-

Hexagonal Tube & Pentagonal shape Tube Machinery

-

Steel Triangle Tube Roll Forming Machine Manufacturer

-

Welding Hardware Sheet Metal Blanks Stamping Parts with OEM vehicle parts car automotive accessories metal sintered stainless steel in technique company manufacture

-

High Precision Sintered Pm Powder Metal Components speed reducer gear positive speed gearbox front terminal end gear double gear herring bone gear angle grinder

-

OEM Powder Metallurgy Mold Parts Suppliers Driven External Spur Enicycloid Bevel Gear sun gear for industry

-

Thick Flat Oval Tube Roll Forming Machine

-

Multiple Steel Tube 8 Types Square Tube Roll Forming Machine 8 in 1

-

Thick Oil Tube Roll Forming Machine Rectangular Pipe 6mm

-

Auto half shaft upsetting processing,camshaft,sucker rod,valve stem and other unregular forgings processing