Home > Company News > What is Medical plastic injection mold core pulling mould?

Company News

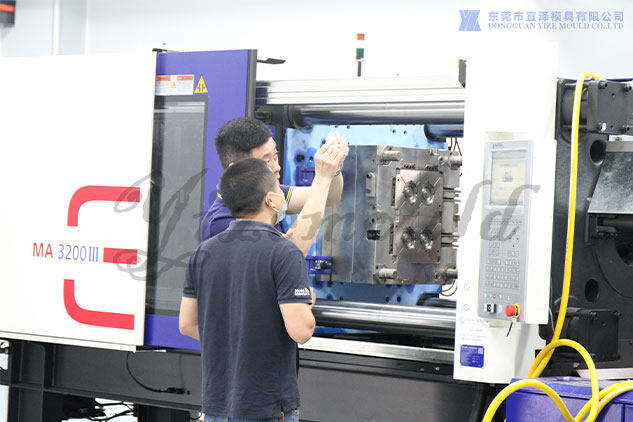

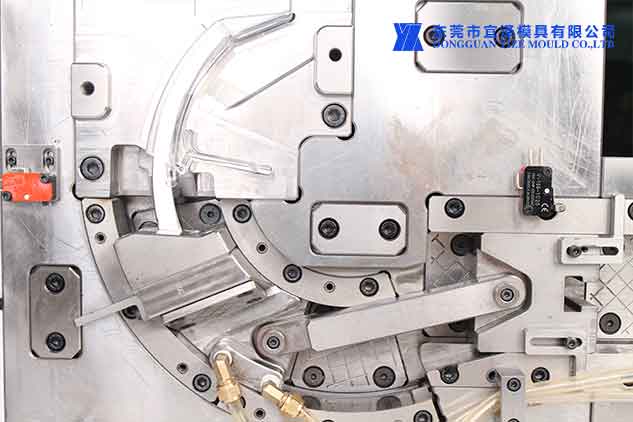

The definition of Medical plastic injection mold core pulling mould is as follows: Any features that will interfere with the direction of the product and the direction of leaving the mold cannot be demolded. In places like this, it is necessary to remove the interfering steel material after the mold is opened (some Time is before the mold is opened) to remove it first to ensure that the product is smoothly removed from the mold. Therefore, the mechanism that realizes such a function is called Medical plastic injection mold core pulling mould.

Sometimes due to the Medical plastic injection mold project product structure, the lateral core pulling mechanism cannot be used, and a strong release mechanism can be considered. However, the position that cannot be demolded should not be too large, and the molding material is relatively soft, such as PP material.

From the perspective of the front and rear molds, the core pulling mould can be divided into the front core pulling mould and the rear mold core pulling. The structure of the front core pulling mould is a little more complicated than the rear mold core pulling. In the case of cores, try to design as back mold core pulling.

Sometimes the core-pulling mechanism cannot be designed on the inside of the product for the position that cannot be demolded, and it can be considered as a sloping roof. Therefore, the inclined roof is also a kind of mold core pulling.

There are many structures of Medical plastic injection mold core pulling mould, which are ever-changing, such as: inner pulling, outer pulling, oblique pulling, side pulling, and arc pulling. No matter what kind of core pulling, the core idea is to make the steel material that cannot be demolded into the core pulling first, and then the product can be taken out. Otherwise, the product cannot be taken out, and even if it is pulled out hard, the product will be damaged, which is unwilling to accept any customer.

This article is reprinted to https://www.yizemould.com/newsdetail-876.html

-

China Manufacturer Custom Metal Pm Powder Metallurgy Parts internal gear external spur gear internal spur gear cylindrical gear sprial bevel gear straight bevel

-

ERSA wave soldering accessories high imitation selective wave soldering nozzle, standard size are in stock

-

Customized hot staming metal component mould

-

Customized cheap Chinese stamping die mould for Auto parts

-

OEM Customized Stamping Parts Metal Stamping die progressive die

-

18 years Stamping mold factory progressive die Stamping Die Tooling for auto parts

-

Vehicle model car mold metal stamping tools progressive die Stamping Die Tooling for auto parts

-

High quality Customized hot stamping vehicle metal parts mould

-

Customized Cheap Product Sheet Metal Stamping Punch Mould Tooling

-

ISO9001 factory Free 3D design custom precision metal press tool from Sobede

-

Customized stamping molds for automotive components

-

Metal Bending Stamping Metal Part OEM vehicles car automotive parts accessories metal sintered stainless steel powder metallurgy technique company manufacture

-

Plastic PP Membrane Hot Chamber vertical Frame membrane filter press plate mold

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15 stainless picture frame OEM Machine Mechanical stainless steel fabrication For Furniture Parts

-

CNC Processing Fabrication Custom Design Metal Machinery Machining ar 15stainless picture frame OEM Machine Mechanical stainless steel fabrication For Furniture Parts

-

Hexagonal Tube & Pentagonal shape Tube Machinery

-

Steel Triangle Tube Roll Forming Machine Manufacturer

-

Welding Hardware Sheet Metal Blanks Stamping Parts with OEM vehicle parts car automotive accessories metal sintered stainless steel in technique company manufacture

-

High Precision Sintered Pm Powder Metal Components speed reducer gear positive speed gearbox front terminal end gear double gear herring bone gear angle grinder

-

OEM Powder Metallurgy Mold Parts Suppliers Driven External Spur Enicycloid Bevel Gear sun gear for industry

-

Thick Flat Oval Tube Roll Forming Machine

-

Multiple Steel Tube 8 Types Square Tube Roll Forming Machine 8 in 1

-

Thick Oil Tube Roll Forming Machine Rectangular Pipe 6mm

-

Auto half shaft upsetting processing,camshaft,sucker rod,valve stem and other unregular forgings processing